Üretilen tüm Lityum pil BMS'lerimiz, 3 yıl kalite garantisi veriyoruz, hasar insan tarafından yanlış işlemden kaynaklanırsa, ücret karşılığında onarım yapacağız

1. BMS profesyonel bir aksesuardır.Birçok çalıştırma hatası ürünün hasar görmesine neden olur, bu nedenle lütfen uyumluluk işlemi için talimat kılavuzunu veya kablolama video eğitimini izleyin.

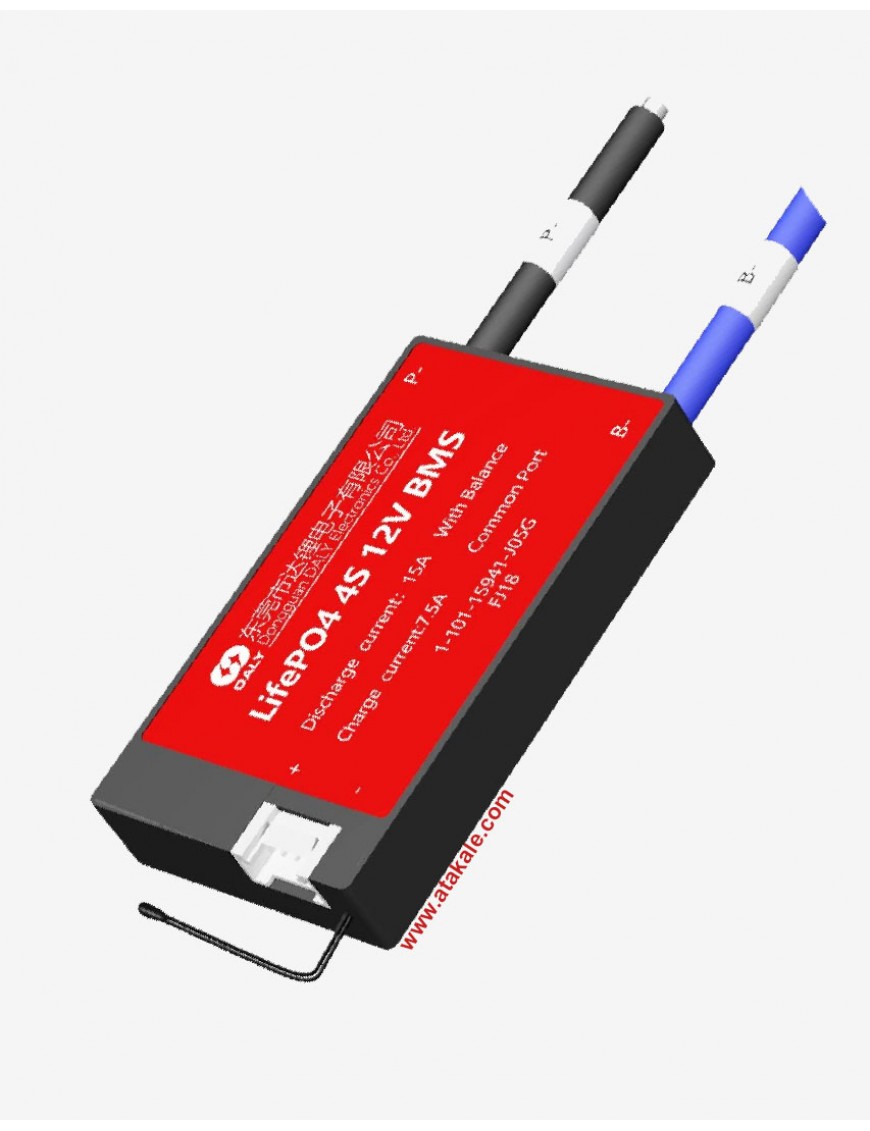

2. BMS'nin B- ve P- kablolarını ters bağlamayanız, kablolamayı karıştırmayınız

3.Li-ion, LiFePO4 ve LTO BMS evrensel değildir ve farklı BMS kullanılması grekir, karışık kullanamazsınız

4.BMS yalnızca aynı dizilere sahip pil takımlarında kullanılabilir.

5. Aşırı akım durumu için BMS'yi kullanmak ve BMS'yi makul olmayan bir şekilde yapılandırmak kesinlikle yasaktır.BMS'yi nasıl doğru seçeceğinizi bilmiyorsanız lütfen müşteri hizmetlerine danışın.

6. Standart BMS'nin seri veya paralel olarak kullanılması yasaktır.Paralel veya seri bağlantı kullanılması gerekiyorsa detaylar için müşteri hizmetlerine danışınız.

7. Kullanım sırasında BMS'nin izinsiz sökülmesi yasaktır.BMS, özel olarak söküldükten sonra garanti politikasından yararlanmaz.

8. BMS'mizin su geçirmez işlevi vardır.Bu pimler metal olduğundan, oksidasyon hasarını önlemek için suya batırılmaması gerekir

9. Lityum pil paketinin özel lityum pil ile donatılması gerekir şarj cihazı, diğer şarj cihazları karıştırılamaz, voltaj dengesizliği vb. önlemek için MOS tüpünün bozulmasına neden olur.

10.Smart BMS'nin özel parametrelerini değiştirmeden revize etmek kesinlikle yasaktır. izin.Değiştirmeniz gerekiyorsa lütfen müşteri hizmetlerine başvurun.Yetkisiz parametre değişikliği nedeniyle BMS'nin hasar görmesi veya kilitlenmesi durumunda satış sonrası servis sağlanamaz.

11. DALY BMS'nin kullanım senaryoları şunları içerir: Elektrikli iki tekerlekli bisiklet, forkliftler, turistik araçlar, E-üç tekerlekli bisikletler, düşük hızlı Dört tekerlekli, RV enerji depolama, fotovoltaik enerji depolama, ev ve dış mekan enerji depolama vb. BMS'nin özel koşullarda veya amaçlarla kullanılmasının yanı sıra özelleştirilmiş parametreler veya fonksiyonlar, lütfen önceden müşteri hizmetlerine danışın.

1. Koruyucu pano bağlantısı akü kablolarının sırası:

Özel dikkat: Farklı üreticilerin tel kabloları aynı standartta değildir, lütfen he-uyumlu kablolar kullandığınızdan emin olun; farklı üreticilerin B ve P çizgilerinin renkleri farklıdır, lütfen B ve P işaretlerine dikkat edin.

1. Unutma!!! Örnekleme tel kablosunu kaynak yaparken, kabloyu BMS'ye sokmayın.

2. Kablo, toplam negatif elektrot B'yi ince siyah çizgiden bağlar. İkinci kablo (kırmızı kablo), ilk pil dizisinin pozitif kutbuna bağlanır. Her pil dizisinin pozitif elektrotunu, toplam pozitif B+'nın son kablosuna kadar sırayla bağlayın.

Daly 4S 12V 15A Smart BMS

Aşırı Düşük Deşarj Gerilim Koruması

Akıllı Kısa Devre Koruma Sistemi

Akıllı Dengeleme Sistemi Bluetooth

Elektrikli araç enerji depolama BMS

Aşırı Şarj ve Akım Koruma Sistemi

Plastik Enjeksiyon Su Geçirmezlik

Daly Smart UART, RS485 and CAN

Altıncı Nesil aktif dengeleme tekniği

BMS Voltaj Aralığı

BMS Akım Kapasite Aralığı

Hücre Sayısı Aralığı

Gümrük tarife GTIP :8536300000

Profesyonel Proje Ürün Gurubudur. Ürün sipariş edildiğinde sizin için 7 gün içinde üreticiden /ithalatçıdan tedarik edilerek özel sipariş olarak gönderilecektir. Aceleniz var ise lütfen iletişme geçerek stok öğrendikten sonra satın alınız. Son Kullanıcı Tüketici Elektronik Ürünü Değildir. Satın Alma Şartları , değişim , iade ve garanti şartları tüketici korunma haklarınını içermez. Ticaret Kanunu hükümleri geçerlidir. Sadece bayi ve tüccarlara satış yapılmaktadır. Satın alan kişi bu ürünü kullanmaya yeterli bilgisi ve eğitimi yok ise almamasını tavsiye ediyor.

Dongguan Daly Electronics Co., Ltd., 2015 yılında Ar-Ge, üretim ve satışı entegre ederek ve enerji depolama sistemleri için kullanılan LiFePO4 BMS, NMC BMS, LTO BMS gibi lityum pil koruyucu panoların üretiminde uzmanlaşmış olarak kurulmuştur. depolama, elektrikli araçlar, elektrikli aletler, elektrikli tekerlekli sandalyeler, AGV'ler ve forkliftler vb. gibi araçlar içindir. Daly BMS'nin özellikleri 3S - 32S, 12v-120v ve 5A-500A'dır. Akıllı BMS, BT, UART, RS485, can, LCD ve GPS özellikleri mevcuttur. Avrupa, Asya ve Kuzey Amerika'da en poüler BMS ürticisidir. Daha yüksek teknoloji BMS geliştirmeye devam etmek için sürekli ürünlerde yenilik yapmaktadır.

18650, 32650, 21700, prizmatik hücreler vb. içinDALY BMS Kullanılabilir.

1. Tüm ürünlerinde japon seiko nun üst düzey entegre devrelerini kullanmaktadır

2. Güçlü anlık yüklere göre dizayn edilmiştir. Sürekli akım aralığı 25/35A/45A/60A/100A.... dir , Tehlikeli yüksek gerilimlere karşı dirençlidir ve korumalıdır, Düşük iç dirence sahip mosfetler kullanılmıştır. Enerji kayıpları çok düşükturi. Soğutucu termodinamik olarak her türlü ortamda çalışacak şekilde dizayn edilmiştir

3. Daly İşlemcisi'nin kendisi güç dengeleme işlevine sahiptir. Devre basit ve güvenilirdir.

4.Her hücre için gerekli şarj voltaj tespiti yapılır. Böylece her pilin aşırı şarj edilmesi veya aşırı deşarj olması önlenir. Aşırı akım ve kısa devre koruma fonksiyonu çok güvenilirdir. Yükün uzun süreli kısa devresi PCB'yi ve aküleri hücreleri etkilemez. Şarj ve deşarj sırasında sıcaklık koruması vardır.

5. Çok düşük güç harcaması. BMS toplamda çalışması için 50uA den daha az akım çekmektedir. Buda uzun süre bekleme sağlamaktadır

6. BMS PCB bordu korozyona, neme , çevre şartlarına dayanıklı dizayn edilmiştir. BMS suya karşı dirençlidir, yüksek empedanslı ESD uyumlu Kaplama Daly Smart BMS yi için çok yönlü koruma ve dayanıklılık sağlar ve uzun süreli kullanımınıza için imal edilmiştir. 4S,8S,16S, 20S ve 24S için Smart lifepo4 BMS hakkında bilgi için lütfen aşağıya bakın.

Android veya iPhone Uygulaması mevcuttur. Bluetooth ile bağlantı kurulup Tamamen Programlanabilir Akıllı BMS 'dir.

Aynı bağlantı noktasını kullanarak şarj ve deşarj tasarıma sahiptir.

Koruma Özellikleri: Daly BMS, lityum akü hücreleri koruması için özel olarak yüksek kaliteli IC/Entegre çipi ile tasarlanmıştır..

Aşırı şarj, aşırı deşarj, voltaj dengelemede yüksek algılama hassasiyeti derecesi gibi korumaları vardır

Aşırı deşarj ve aşırı akım algılamalarının korunması ve algılama sürecindeki gecikme sürelerini kontrol eder.

Şarj ederken aşırı gerilime karşı koruma Düşük sıcaklıkta şarj koruması a -1c.

Otomatik tespit SOC işlevli Hassas SOC hesaplamalı BMS. .

Otomatik olarak şarj işlemi Lifepo4 şarj algoritmasına göre yapılır. Veya statik sabit akım ile şarj etme seçeneği

Lifepo4 hücrenin/pilin çalışma durumunu algılamayı ve kablosuz bluetooth üzerinden bazı parametreleri ayarlamayı yönetmek için cep telefonu yazılımı mevcuttur.

Akıllı iletişim, insan-bilgisayar etkileşimi zekası

Daly Akıllı BMS üç farklı haberleşme protokolüne sahiptir. UART, RS485 ,CAN, protokolleri üzerinden PC SOFt yazılımıyla haberleşme yapabilir. Mobil cihazlardan BMS akü, bilgilerini görebilir ve yönetebilirsiniz.Ana akım invertörler ve Daly özel protokolü gibi iletişim protokollerinin özelleştirilmiş yapılarına sahipseniz, daly BMS yi istediğiniz gibi kendi yazılımınızla çalıştırabilirsiniz

SMARTBMS APP ile bağlantı

Daly BMS ler için cep telefonu APP geliştirmiştir. Bluetooth, BMS'ye bağlandıktan sonra, BMS, pil verilerini, pil voltajı, toplam voltaj, sıcaklık, güç, alarm bilgileri, şarj Deşarj anahtarı gibi ilgili parametreleri gerçek zamanlı olarak izleyebilen cep telefonu APP'ye bağlanabilir.

Daly “Smart” BMS

BMS, yalnızca voltaj ve akıma karşı yüksek hassasiyetli algılama ve yüksek hassasiyetli yanıt gerçekleştirerek lityum piller için büyük koruma sağlayabilir. Daly standart BMS, pilin verimli çalışmasını ve kolayca çalışmasını sağlamak için ± 0.025V içinde voltaj doğruluğu ve 250 500us kısa devre koruması elde etmek için yüksek hassasiyetli çipi mevcuttur. Hassas devre algılama ve bağımsız olarak yazılmış çalışma programı ile IC çözümü dünyada benzersiz özelliklerdedir. Çözüm basit ve güvenlidir. Karmaşık çözümlerle uğraşmak zorunda kalmazsınız

Ana kontrol çipi için flaş kapasitesi 256/512K'ya kadar yükseltilebilir. Çip entegreli zamanlayıcı, CAN, ADC, SPI, I2C, USB, URAT ve diğer çevresel işlevler, düşük güç tüketimi, uykuda kapatma ve bekleme modları gibi avantajlara sahiptir. Daly'de 12-bit ve 1us dönüşüm süresine sahip 2 DAC'ye sahiptir. (16'ya kadar giriş kanalı vardır)

Yüksek kalitede meteryallerle imal edilmiştir

Daly akıllı BMS, yüksek akıma dayanabilen profesyonel bakır levha ile donatılmıştır. yüksek akım dayanıklı tasarımı, yüksek akım bakır levha ve oluklu alüminyum ısı emici gibi yüksek kaliteli bileşenleri içerir.

Kapsamlı kişiselleştirilmiş özelleştirme hizmetlerini destekler

Daly, uzun yıllardır BMS endüstrisine en büyük market sahibi olarak dahil olmuştur ve bireysel ihtiyaçlarınızı karşılamak için çeşitli avantajlar sunar. Ar-Ge ekibi, her bir talebin kapalı bir döngü içinde yanıtlanmasını sağlamak için bir ilk talep sorumluluk sistemi uygular. 13 akıllı üretim hattı, 20.000 metrekarelik anti-statik atölye, güçlü esnek üretim gücü ile Daly, ürünlerin kalitesini ve teslimat hızını sağlayabilir.

Güçlü üretim kapasitesi ve zamanında teslimat

Daly'nin yıllık 10 milyondan fazla çeşitli BMS türü üretimi vardır ve yeterli geleneksel envantere sahiptir. Özelleştirilmiş ürünler, müşteri siparişlerinden prova, seri üretim ve nihai teslimata kadar sınırlı bir süre içinde hızlı bir şekilde teslim edilebilir. Dünya çapında 130'dan fazla ülke ve bölgede bulunan müşteriler, Lithium'un profesyonel, yüksek kaliteli BMS çözümlerinden şimdiden yararlandı.