-Victron Energy Lifepo4 Kurulumuyla ilgili önemli uyarılar

Paketi kullanmadan ve taşımadan önce, dikkatle ekteki 'Şarj Edilebilir Lityum İyon Akü Paketi için Kullanım Talimatı'na bakın.

Güvenlik nedeniyle, şarj edilebilir aküler düşük kalan kapasite durumunda gönderilmez. Kullanmadan önce şarj edin. Kullanmak için birden fazla akü paketini paralel veya seri olarak bağlamayın. Bu, pil takımına, hatta ekipmanınıza bile zarar verebilir.

-Garanti

Üretici, sevkıyat tarihinden itibaren 60 ay boyunca kusurlara veya kötü işçiliğe karşı akü takımını değiştirmekten sorumlu olacaktır. Ekipmanın arızalanmasından veya pilin yanlış kullanılmasından kaynaklanan diğer sorunlar bu garanti kapsamında değildir.

- LiFePO4 Akü Paketi için Kullanım Talimatı Kılavuzu

-. Genel

Victron Energy veya Uyumlu firmalar tarafından sağlanan akü paketleri, spesifikasyona göre dikkatli bir şekilde kullanılmalıdır. Burada

biraz daha izlenecek.

- Paketin saklanması

Paketlerin aşağıdaki koşullarda saklanması talep edilir:

a. Paketler veya kartonlar üzerinde doğrudan güneş ışığı almayan serin bir ortamda iç mekanda depolama.

b. Pilleri düşük nemli ve - 20°C ila +30°C sıcaklık aralığında kuru bir yerde saklayın. durumunda

c. Uzun süreli saklama, akünün kendiliğinden boşalmasını hızlandırabilir ve akülerin devre dışı kalmasına neden olabilir.

devre dışı bırakma etkisini en aza indirin, akü paketlerini +10°C ila +30°C sıcaklık aralığında saklayın. d. Uzun süreli depolamadan sonra ilk kez şarj edilirken, paketlerin devre dışı bırakılması şarjın azalmasına neden olmuş olabilir. kapasite. Birkaç tam şarj ve deşarj döngüsünü tekrarlayarak bu tür paketleri orijinal performansına geri getirin.

e. Paketleri 6 aydan daha uzun süre sakladığınızda, sızıntıyı önlemek için her 6 ayda bir en az bir kere şarj edin ve kendi kendine deşarj nedeniyle performansta bozulma.

-. Şarj paketi

a. Belirtilen voltaj ve akıma sahip uygun şarj cihazı kullanın. Victron Energy akıllı alifepo4 şarj cihazını şiddetle tavsiye ederiz. Şarj cihazı imalatının kullanımını veya özelliklerini önerebiliriz. Bununla ilgili bilgi almak istiyorsanız, lütfen bizimle iletişime geçin.

b. Asla ters şarj etmeye çalışmayın. Kutupları ters olarak şarj etmek, akü kutuplarının ters çevrilmesine neden olarak akünün içindeki gaz basıncının yükselmesine ve bu da paketteki akülerin akmasına neden olabilir.

c. Aşırı şarjdan kaçının. Tekrarlanan aşırı şarj, paket performansında bozulmaya yol açabilir. Ve Aşırı ısınma meydana geldi.

d. Şarj verimliliği 40°C'nin üzerindeki sıcaklıklarda düşer.

- Beklenmedik hasarlara karşı koruma

a. Metal tel, kolye, zincirlerde (+) ve/veya (-) uçları bağlanmamalıdır.

b. Olası arıza veya hasarları önlemek için paketleri yüksekten düşürmeyin.

c. Olası hasarları önlemek için paketleri bükmeyin veya bükmeyin.

- Güvenlik için

a. Paketleri sökmeyin.

b. Koku, deformasyon, renk bozulması vb. gibi anormal bir şey bulunduğunda paketi kullanmayın.

d. LiFePO4 hücrelerini veya diğer parçaları paketlerinden çıkardıktan sonra tekrar kullanmayın.

e. Elektrolit sızıntısı meydana geldiğinde sıvıya dokunmayın.

Kurulum Yeri

Kurulum konumunun aşağıdaki koşulları karşıladığından emin olun:

1) Alan tamamen su geçirmezdir

2) Zemin düz ve düzdür.

3) Yanıcı veya patlayıcı madde yoktur.

4) Ortam sıcaklığı 0°C ila 50°C aralığındadır.

5) Sıcaklık ve nem sabit bir seviyede tutulur.

6) Alanda minimum toz ve kir var.

7) Isı kaynağına olan mesafe 2 metreden fazladır.

8) İnverterin hava çıkışına olan mesafe 0,5 metreden fazladır.

9) Kurulum alanları doğrudan güneş ışığından korunmalıdır.

10) Akü modülü için zorunlu havalandırma gerekliliği yoktur, ancak lütfen kapalı alanda kurulumdan kaçının. Havalandırma aşağıdakilerden kaçınacaktır: yüksek tuzluluk, nem veya sıcaklık topraklama

Topraklama kabloları 10AWG veya üzeri sarı-yeşil kablolar olmalıdır. Bağlantıdan sonra, akü topraklama noktasından odanın veya kurulu yerin Toprak bağlantı noktasına olan direnç 0,1Ω'den küçük olmalıdır.

1) modülün yüzeyi ile rafın yüzeyi arasında doğrudan temas eden metal olmamalıdır tam izolasyon sağlanmalıdır. Boyalı raf kullanılıyorsa, ilgili yer boyayı kaldıracaktır.

2) modüllerin topraklama noktasına bir topraklama kablosu bağlayın ve kabini bu topraklama barasına bağlayınınız

1) Aküleri kabine koyun

2) 4 adet vidayı sürün

3) Akü modülleri arasındaki kabloları bağlayın

4) Kabloları invertöre bağlayın

Sorun giderme.

dayalı sorun belirleme

1) Akünün açılıp açılmayacağı

2) Pil açıksa, kırmızı ışığın kapalı olduğunu, yanıp söndüğünü veya yandığını kontrol edin.

3) Kırmızı ışık yanmıyorsa, pilin şarj edilip edilemeyeceğini kontrol edin. Olası koşullar: 1) Pil açılamıyor, AÇIK konuma getirin ve kırmızı SW'ye basın, ışıkların hepsi yanmıyor veya yanıp sönmüyor.

a) Kapasite çok düşük veya modül aşırı boşalmış. çözüm: 48-53,5V voltaj sağlamak için bir şarj veya invertör kullanın. Pil başlayabiliyorsa, modülü şarj etmeye devam edin ve pil günlüğünü kontrol etmek için izleme araçlarını kullanın.

Akü terminal voltajı ≤45Vdc ise, SOH'den etkilenmemek için modülü yavaşça şarj etmek için lütfen ≤0.05C kullanın. Akü terminal voltajı >45Vdc ise, şarj etmek için ≤0.5C kullanabilir.

Pil başlayamıyorsa, pili kapatın ve onarın.

2) Pil açılabilir, ancak kırmızı ışık yanıyor ve şarj olmuyor veya deşarj olmuyor. Kırmızı ışık yanıyorsa, sistem anormaldir, lütfen değerleri aşağıdaki gibi kontrol edin.

b) Sıcaklık: 60°C'nin üzerinde veya -10°C'nin altında pil çalışmayabilir. Çözüm: Pili 0°C ile 50°C arasındaki normal çalışma sıcaklığı aralığına taşımak için

c) Akım: Akım 90A'i geçerse pil koruması devreye girer. Çözüm: Akımın çok büyük olup olmadığını kontrol edin, varsa güç kaynağı tarafındaki ayarları değiştirin.

32

d) Yüksek Voltaj: Şarj voltajı 54V'un üzerinde ise akü koruması devreye girer. Çözüm: Güç kaynağı tarafındaki ayarları değiştirmek için voltajın çok yüksek olup olmadığını kontrol edin. Ve modülü boşaltın.

e) Düşük Voltaj: Akü 44,5V veya altına düştüğünde akü koruması devreye girer. Çözüm: Kırmızı ışık sönene kadar pili şarj edin.

f) Hücre voltajı yüksek. Modül voltajı 54V'tan düşük, SOC LED'i tamamen yanmıyor. Deşarj olduğunda modül koruması kaybolur. Çözüm: Modülü 53-54V ile şarj edin veya sistem döngüsünü koruyun. BMS, döngü sırasında hücreyi dengeleyebilir.

3) Kırmızı LED açıkken şarj ve deşarj yapılamıyor. Sıcaklık 0

50 derecedir. Şarj etmek için şarj cihazını kullanın, mümkün değil. Boşaltmak için yük kullanın, mümkün değil.

g) Kalıcı koruma altındadır. Tek hücre voltajı 4.2'den yüksek veya 1.5'ten düşük veya sıcaklık 80 dereceden yüksek. Çözüm: Modülü kapatın ve onarım için yerel distribütörünüzle iletişime geçin.

4) Kırmızı LED yanmadan şarj ve deşarj yapılamıyor. Sıcaklık 0

50 derecedir. Şarj etmek için şarj cihazını kullanın, mümkün değil. Boşaltmak için yük kullanın, mümkün değil.

h) Sigorta bozuk. Çözüm: Modülü kapatın ve onarım için yerel distribütörünüzle iletişime geçin.

LifePo4 Bakımı

• Müşteri aküyü teslim aldığında, öncelikle temel işlevi kontrol etmeli ve nakliye sırasında herhangi bir hasar oluşmadığından emin olmalıdır. Lütfen lifepo4 voltajını, şarj işlevini, deşarj işlevini ve görüntüleme işlevini test edin; Herhangi bir anormallik varsa lütfen kurulumu durdurun ve hemen bize bildirin. akünün kurulum kılavuzuna göre taktıktan sonra, ilk kez kullanmadan önce aküyü tamamen şarj edin. akü , üç ila beş kez tam olarak şarj edilip boşaldığında maksimum kapasitesine ulaşacaktır.

• Ömürlerini uzatmak için aküleri kapasiteleri düşükken şarj edin. Bu süre içinde piller şarj edilmezse ve uzun süre eksik kalırsa akü ömrü olumsuz etkilenecektir. Bu aküler uzun süre kullanılmayacaksa, yarı kapasitede tutun ve aküyü iki ayda bir, her seferinde bir saat yüzer şarj edin.

• Batarya kuru, temiz ve iyi havalandırılan bir alana kurulmalı, bu arada tutuşma kaynaklarından ve yanıcı malzemelerin yakınından kaçınılmalıdır. Şarj sırasında yükün bağlantısını kestiğinizden (yani elektrikli ekipmanı kapattığınızdan) emin olun.

• Pilin çalışma sıcaklığı 41–104°F'dir. (Optimum çalışma sıcaklığı 59–95°F'dir.) Bu sıcaklık aralığının dışında pilin performansı değişebilir. Bu şartlar altında kapasitenin veya ekipmanın çalışma süresinin değişmesi normaldir.

• Akü kutusunu organik çözücülerle temizlemekten kaçının.

• Bir kaza olursa, yangını söndürmek için karbondioksit kullanmayın; bunun yerine, söndürmek için karbon tetraklorür veya kum kullanın.

• Lifepo4 bir sarf malzemesidir ve kullanım ömrü sınırlıdır. Lütfen pil kapasitesi nominal kapasitenin %50'sinden düşük olduğunda aküyü değiştirin.

LifePo4 Akülerin paralel olarak şarj edilme voltajı

LiFePO4 aküler paralel olarak bağlarken, hizmete almadan önce lütfen her bir pilin 0.1V aralığında olduğundan emin olun, Bu, aküler arasındaki dengesizlik olasılığını en aza indirecektir. 12V LiFePO4 akü şarj ediyorsanız, şarj voltajı 14V – 14,2V arasında olmalıdır. 24V aküleri paralel olarak şarj ederken, şarj voltajı 28V – 28.4V olmalıdır. 36V lityum akü paralel olarak şarj etmek için 42V – 42,6V voltaj gerekir. Son olarak, 48V LiFePO4 aküleri şarj etmek için 56V – 56.8V voltaj parametreleri gerekir. Aşağıda, her sistem voltajı için voltaj gereksinimlerini gösteren bir özet içeren bir tablo bulunmaktadır.

Sistem Gerilimi ........Şarj Voltajı

12V.......................14V – 14.2V

24V....................... 28V – 28,4V

36V.......................42V – 42.6V

48V.......................56V – 56.8V

Voltaj parametreleri hem CC hem de CC-CV şarj profilleri için geçerlidir. Şarj cihazınızın voltajı tabloda listelenenlerden daha düşükse, akünüze zarar vermez, ancak yetersiz şarj olur ve akünün tam nominal kapasitesini sağlamaz. Şarj cihazınızın voltajları yukarıdaki tablolarda listelenenlerden daha yüksekse, BMS akünün bağlantısını kesebilir ve yeniden bağlanmak için yükü kaldırmanız gerekebilir. Bu rahatsızlıktan kaçınmak için şarj cihazını değiştirmenizi ve yüksek kaliteli bir LiFePO4 akü şarj cihazına yatırım yapmanızı öneririz.

lifePo4 Akülerin Seri olarak şarj edilmesi

LifePo4 akülerin seri şarj edilmesi

Aküleri seri olarak bağlarken, hizmete almadan önce lütfen her akünün birbirinden 50mV (0,05V) dan fazla olmadığından emin olun. Bu, aküler arasında bir dengesizlik olasılığını en aza indirecektir. Akülerinizin dengesi bozulursa, herhangi bir akü voltajı setteki başka bir aküden 50mV (0,05V) ise, yeniden dengelemek için her aküyü ayrı ayrı şarj etmelisiniz. Dengesizliği önlemek için her aküyü periyodik olarak ayrı ayrı şarj edebilirsiniz. LiFePO4 aküleri seri olarak şarj ederken, hücrelerin dengeli kalmasını sağlamak için her akü ayrı ayrı şarj eden çok sıralı bir şarj cihazı kullanmak en iyisidir. Sisteminizi bir bütün olarak şarj etmek istiyorsanız, 24V akü LiFePO4 şarj cihazı veya 48V pil LiFePO4 şarj cihazı da kullanabilirsiniz.

Tabii unutmayalım, bu işlemi her şarj ederken uygulamak gerekecektir. Buda pratik olmayacağından, aküleri seri bağlamayınız, akülerinizi tamamen kaybetmenizi sebep olur.

Voltaj parametreleri hem CC hem de CC-CV şarj profilleri için geçerlidir. Şarj cihazınızın voltajı tabloda listelenenlerden daha düşükse, pilinize zarar vermez, ancak yetersiz şarj olur ve pilin tam nominal kapasitesini sağlamaz. Şarj cihazınızın voltajları yukarıdaki tablolarda listelenenlerden daha yüksekse, BMS akünün bağlantısını kesebilir ve yeniden bağlanmak için yükü kaldırmanız gerekebilir. Bu rahatsızlıktan kaçınmak için şarj cihazını değiştirmenizi ve yüksek kaliteli bir LiFePO4 pil şarj cihazına yatırım yapmanızı öneririz.

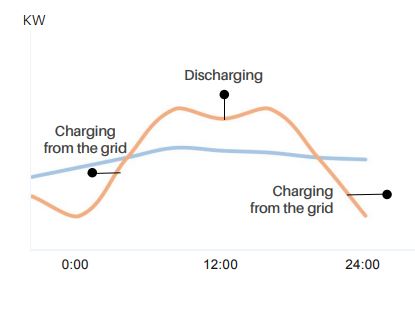

LIFEPO4'ün Akıllı invertör veya Solar şarj kontrol cihazıyla şarj edilmesi nasıldır

Aşağıda, LiFePO4 aküleri şarj etmek için bir invertör/şarj cihazı veya şarj kontrol cihazı kullanırken temel, tipik şarj cihazı girişleri bulunmaktadır. Birçok invertör/şarj cihazı ek parametreler gerektirir,

Şarj Kademesi................12V Sistem.................24V Sistem...................36V Sistem.............48V Sistem

Bulk Şarj Voltajı..................14V – 14.6V.................28V – 29.2V.................. 42V – 43.8V.............56V – 58.4V

Absorption Voltaj................14V – 14.6V.................28V – 29.2V...................42V – 43.8V.............56V – 58.4V

Absorption Süresi................0- 6 dakika................0- 6 dakika...................0- 6 dakika.............0- 6 dakika

Float Voltajı......................13.8V ± 0.2V...............27.6V ± 0.2V..................41.4V ± 0.2V...........55.2V ± 0.2V

Düşük Voltaj Kesme.............11V..........................22V............................33V......................44V

Yüksek gerilim kesme..........14.6.........................29.2V.........................43.8V....................58.4V

LifePo4 Aküleri Hangi Şarj cihazı kullanmalıyız

LiFePO4 pilleri nasıl şarj edilir? Müşterilerimizden aldığımız en yaygın sorulardan biri budur. Cevap basit: Elbette bir LiFePO4 pil şarj cihazı kullanın. LiFePO4 pilleri şarj ederken, tipik olarak LiFePO4'ün gerektirdiğinden daha yüksek voltajla tasarlanmış diğer lityum iyon kimyaları için tasarlanmış bir şarj cihazı kullanmadığınızdan emin olun. Lityum demir fosfatı şarj etmek için kurşun asitli bir pil şarj cihazının kullanılıp kullanılamayacağı sıklıkla sorulur. Kısa cevap, voltaj ayarları LiFePO4 pillerin kabul edilebilir parametreleri içinde olduğu sürece evet.

LiFePO4 şarj cihazını kullanmadan önce şarj cihazınızın kablolarının yalıtıldığını ve kırılmadığını kontrol edin. İyi bir bağlantı ve optimum iletkenlik sağlamak için şarj cihazı terminal konektörleri temiz olmalı ve akü terminalleriyle doğru şekilde eşleşmelidir.

LifePo4 Akülerin şarj gerilim başlangıcı

LiFePO4 aküler tamamen boşalmamışsa, her kullanımdan sonra şarj edilmelerine gerek yoktur. LiFePO4 aküler , kısmi şarj durumunda (PSOC partial state of charge ) bırakıldığında zarar görmez. LiFePO4 akülerinizi her kullanımdan sonra veya %80 DOD'a (%20 SOC) kadar deşarj olduklarında şarj edebilirsiniz. Pil Yönetim Sistemi BMS), düşük voltaj (voltaj 10V olacaktır) nedeniyle akünün bağlantısını keserse, yükü kaldırın ve hemen bir LiFePO4 pil şarj cihazı kullanarak şarj edin.

Lityum Demir Fosfat Aküler Şarj edilem sıcaklığı

LiFePO4 aküler 0°C ila 45°C (32°F ila 113°F) arasında güvenli bir şekilde şarj edilebilir. LiFePO4 aküler , sıcak veya soğuk sıcaklıklarda şarj olurken voltaj için sıcaklık telafisi gerektirmez. Tüm LiFePO4 aküler , düşük ve yüksek sıcaklıklardan koruyan dahili bir BMS ile birlikte gelir. Düşük sıcaklık nedeniyle BMS bağlantısı kesilirse, BMS'nin yeniden bağlanması ve şarj akımını kabul etmesi için akünün ısınması gerekir. Akünün'nin bağlantısı yüksek sıcaklık nedeniyle kesilirse, BMS'nin aküyü şarj etmeyi kabul etmesi için akünün soğuması gerekir. BMS düşük sıcaklık ve yüksek sıcaklık kesme ve yeniden bağlanma değerleri için lütfen özel akünüzün veri sayfasına bakın.

LT lityum pillerin şarj ve deşarj sıcaklığı -20°C ila 60°C'dir. Bazı Düşük Sıcaklık (LT) Lityum Piller, Kanada'nın soğuk iklimleri için tasarlanmış, soğuk hava koşullarına uygundur. Bu piller, şarj cihazından güç çeken tescilli teknolojiye sahip yerleşik bir ısıtma sistemine sahiptir. Ek bileşen gerekmez. Tüm ısıtma ve şarj işlemi tamamen sorunsuzdur. Isıtma sistemi, 0°C'nin altında şarj etmeye çalışıldığında otomatik olarak devreye girer ve ihtiyaç kalmadığında otomatik olarak devre dışı kalır. Isıtma sistemi gücü pilden değil, şarj cihazından alır ve lityum akünün kendi kendine boşalmamasını sağlar ve size güç sağlar. LT lityum akü LiFePO4 şarj cihazına takmanız yeterlidir; gerisini dahili ısıtma ve izleme sistemleri halleder.

LIFEPO4 Aküler Kurşun Asit Şarj cihazlarıyla şarj edilirmi

Çoğu kurşun asitli akü şarj cihazı, uygun voltaj yönergeleri dahilinde oldukları sürece LiFePO4 akülerle kullanılabilir. AGM ve Jel algoritmaları tipik olarak LiFePO4 voltaj gereksinimlerine girer. Sulu akü şarj algoritmalarının voltajı genellikle LiFePO4 şarj gereksinimlerinden daha yüksektir ve bu da BMS'nin bağlantısının kesilmesine neden olur. Böyle bir durumda, şarj cihazınızı bir LiFePO4 şarj profiliyle değiştirmek genellikle iyi bir uygulamadır. BMS aküyü koruduğu için kurşun asitli şarj cihazlarının kullanılması tipik olarak aküye zarar vermez.

Düşük voltaj nedeniyle BMS bağlantısı kesilirse, şarj cihazı LiFePO4'ü şarj etmek için kabul edilebilir şarj parametrelerine sahip olsa bile kurşun asitli akü şarj cihazı BMS'yi yeniden bağlayamayabilir. Bunun nedeni, BMS'nin bağlantısı kesildiğinde, bir voltmetrede 0V okuyacağı için lityum pilin voltajı olmayacak, kurşun asitli şarj cihazlarının ise şarjı başlatmak için akünün bir voltaj okumasını gerektirmesidir. Akü 0V okuyorsa, kurşun asitli akü şarj cihazı bir akü bağlı olduğunu ve şarj olmaya başlaması gerektiğini anlayamayacaktır. Bu, bazı düşük kaliteli lityum şarj cihazları için de geçerlidir. Yüksek performans ve uzun ömür sağlamak için her zaman yüksek kaliteli bir LiFePO4 şarj cihazına yatırım yapmanız önerilir.

DC DC konvertörle ve Alternatörle LifePo4 akülerin şarj edilmesi

Alternatörün kalitesine bağlı olarak, LiFePO4 akülerin değişiklik yapmadan şarj etmek iyi sonuç verebilir. Bununla birlikte, zayıf voltaj regülasyonu olan düşük kaliteli alternatörler, BMS'nin LiFePO4 akülerinin bağlantısını kesmesine neden olabilir. BMS akülerin bağlantısını keserse, alternatör hasar görebilir. LiFePO4 akünüzü ve alternatörünüzü korumak için lütfen uyumlu bir yüksek kaliteli alternatör kullandığınızdan veya bir voltaj regülatörü taktığınızdan emin olun. Ev tipi küçük enerji depolama da dahil olmak üzere akülerinizi güvenli ve etkili bir şekilde şarj etmek için DC'den DC'ye şarj cihazı da kullanabilirsiniz. Bir alternatörle lityum şarjı söz konusu olduğunda, DC'den DC'ye şarj cihazı takmak önerilen seçenektir.

Lityum Demir Fosfat Aküler Kurşun asit akü şarj cihzlarıyla şarj edilirmi

Çoğu kurşun asitli akü şarj cihazı, uygun voltaj yönergeleri dahilinde oldukları sürece LiFePO4 akülerle kullanılabilir. AGM ve Jel algoritmaları tipik olarak LiFePO4 voltaj gereksinimlerine girer. Islak hücre veya sulu akü şarj algoritmaları için voltaj genellikle LiFePO4 gereksinimlerinden daha yüksektir, bu da BMS'nin şarj döngüsünün sonunda pili ayırmasına ve şarj cihazının bir hata kodu göstermesine neden olabilir. Böyle bir durumda, şarj cihazınızı değiştirmek genellikle iyi bir uygulamadır. BMS aküyü koruduğu için kurşun asitli şarj cihazlarının kullanılması aküye zarar vermez.