Atakale güneş enerjisi panellerinin kurulumu için galvaniz çelikten güneş enerjisi destek profilleri üretmektedir. Çelik destek profillerimiz soğuk şekillendirilmiş hafif çelik konstrüksiyon profillerden yapılmıştır. Standart destek profillerinin yanında ayrıca müşteri isteklerine göre özel üretim yapabilmekteyiz. İhtiyaçlarınıza yönelik hazır bir tasarımınız varsa lütfen paylaşmaktan çekinmeyin. Yüksek kalite standartları ve en uygun fiyatlarla hizmet veriyoruz. Roll form makinalarımız, PVC pencere ve kapılar için destek profilleri, güneş paneli destek profilleri, U Profil, C Profil ve ayrıca prefabrik yapı profilleri yapabilmektedir. Ayrıca alçı levha (alçıpan) profilleri de üretmekteyiz.

Başka bir avantajımız, farklı çatı senaryoları için farklı destek çözüm seçeneklerimiz var. C ve U şekilli profillerin kombinasyonu farklı yapılar için kullanılabilir. Ayrıca güneş enerjisi paneli destek bağlantılarında U profil ve Z şekilli çelik profiller kullanılabilir.

Bunun yanında roll form makine parkurumuzda farklı şekil ve formlar üretmekteyiz. Profil formlarımızdan bazıları C, U, CEE, ZEE, SIGMA ve SIGMA + ‘dır. Fabrika ortamında her zaman tüm üretim aşamaları tam otomatik roll-form teknolojisi ile yapılır. Bu nedenle üretimimizde ISO ve EN standartlarını takip ediyoruz.Profillerimizde tüm 90 ° köşelerde iç yarıçap minimum 3 mm’dir. Tüm ölçülerimiz TS EN 1993-1-3 standartlarına uygundur.Diğer yandan müşteri isteklerine bağlı olarak farklı çelik hammadde kaliteleri ile imalat yapılabilmektedir; S390GD + Z / S350GD + Z / DX51D + Z / S235 JR / S355 JR.

Uygulama Yöntemleri

Çakma Zemin Uygulamaları

Aşık: Profil Kolon

Toprak :Çakma Mesafesi

Diyagonel :Dikey Kolon Mesafesi

- Çakma işlemine uygun topraklarda kullanılır.

- Çakma derinliği toprak yapısına ve proje bölgesindeki statik

ve dinamik yüklere göre değişebilir.

- Yüksek kalite hammadde kullanımı ve üretim aşaması ve

sonrasındaki hassas kalite kontrolleri ile çakma işlemindeki

ürün deformasyonlarını minimum seviyeye indirir.

- İleri mühendislik ve tasarımıyla hızlı ve kolay kurulum

avantajı sunar. Bu sayede işçilik maliyetinden ciddi

ölçülerde tasarruf edilmesini sağlar.

Beton Zemin Uygulamaları

ARAZİ UYGULAMA ÇÖZÜMLERİ

Kiriş Kolon Dikey Kolon Mesafesi

- Çakma işlemine uygun olmayan zeminlerde kullanılır.

- Beton zemin ölçüleri projeye göre değişebilir.

- Yüksek kalite hammadde kullanımı ve üretim aşaması ve sonrasındaki hassas kalite kontrolleri ile çakma işlemindeki ürün deformasyonlarını minimum seviyeye indirir.

- İleri mühendislik ve tasarımıyla hızlı ve kolay kurulum avantajı sunar. Bu sayede işçilik maliyetinden ciddi ölçülerde tasarruf edilmesini sağlar.

Tek Ayak Konstruksiyon Uygulaması

Çakma işlemine uygun olmayan zeminlerde kullanılır.

- Beton zemin ölçüleri projeye göre değişebilir.

- Yüksek kalite hammadde kullanımı ve üretim aşaması ve sonrasındaki hassas kalite kontrolleri ile çakma işlemindeki ürün deformasyonlarını minimum seviyeye indirir.

- İleri mühendislik ve tasarımıyla hızlı ve kolay kurulum avantajı sunar. Bu sayede işçilik maliyetinden ciddi ölçülerde tasarruf edilmesini sağlar.

Güneş Paneli Çatı Montaj Rayı

Yüksek Mukavemetli Tasarım

Yer ve Çatı Güneş Panel Montajı

Saf Anodize Eloksal Kaplama

Güneş Paneli En-Aw 6063 T6 Sertlik

Prefabrik Dizayn Kolay Montaj

Ekonomik , 30 Yıl Ömürlü, Garantili

Rüzgar ve Kar yüküne dayanıklı

Dikey veya Yatay montaj Kullanımı

Güneş Paneli Çerçeve Kalınlığı

Kullanım Alanları

Ray Uzunluğu

20mm-50mm

Şıngıl, Sandviç Panel, Trapez,Yer

20mm-6000mm

GTIP Gümrük Tarife HS Kod :8541402000

Güneş Paneli Konstruksiyon - C120x50x25x4 4mm -sıcak galvnanizli 7.98kg/metre

Yere düz zemine kurulan galvanize veya boyalı boyasız olarka isteğe uygun olarak üretilmektedir. Ürün 3 farklı ana parçadan oluşmaktadır

Ön Kolon (Front Column) kısa ve güneşe bakan tarafta flanşlı gömmeli tip olarak iki türlü üretilir.. Güneş enerji montaj kolonu 4 lü , 2 li, tekli olarak farklı paneller dizilimleri için özel boylarda üretilir.

Arka Kolon (Back Column) konstruksiyonun uzun arka kısmındaki kolondur.flanşlı gömmeli tip olarak iki türlü üretilir.. Güneş enerji montaj kolonu 4 lü , 2 li, tekli olarak farklı paneller dizilimleri için özel boylarda üretilir.

Kiriş (Beam) Konstruksiyonun iki kolon arasında aşıkları taşıyan profildir. Kiriş üzerindeki kolon ve aşıkların bağlantısını sağlayan delikler panel dizilimine göre üretilir.

Aşık (rail joiner) güneş paneli konsturskiyonun panlleri taşıyan profillerdir. her panelin altında iki adet veya ii panel için 3 lü olarak üretilir. Panel ağırlığı , kolonlar arası mesafe ve dizilimlere göre kesit seçilir. Kolon kiriş üstünde alüminyum olarakda tercih edilebilir.

Flanş (Flange) Ön ve Arka kolonlarda beton ve çatı üstüne çelik dübel kimyasal dübel ile monte edilecekse ve gömülmeyecekse tabana bir levha kaynatılır. Bu levha kolono betona birleştir.

C profillerle kosntruksiyon kurulumu yaygın 3 ayrı kategoride incelenebilir.

1. Panel Büyüklüğü

340W*285W /385WHC Güneş panelleriyle

2xDikey Montaj

4xYatay Montaj

410W güneş panelleriyle

2xDikey Montaj

4xYatay Montaj

455W HC Güneş Panel

2xDikey

4xYatay Montaj

455W HC Güneş Panel

2xDikey

4xYatay Montaj

2. Yere, zemine, çatıya montaj şekli olarak

Yere çakılarak

Yere çakılması durumunda panellerin en uç kısmı kar yüksekliği olan 60cm den daha yüksekde durması için gerekli ölçü +Yere çakılacak miktar olarak düşünmek gerek. Standart statik değerler açısında yere yapılacak sistem 1.5mt toprağa gömülmesi gerekir. Eğer toprak değilse taşsa bunu rack makinasıyla delerek delinen zemine 60cm den az olmamak akydıyla bton dökülerekde yapılabilir

Yere betonla Flanşla

Güneş panelleri zemine beton atılarak montaj yapılacaksa , beton ölçüleri minumum 150cmx50cmx40cm(yükseklik) olmalıdır. Beton yüksekliği dikkat alınarak kolon uzunlukları daha kısa yapılabilir. Minumum kolon yüksekliği ön kolon /kısa olan 80cm , arka kolon uzun olan ise 154 cm olmalıdır.

Eğer 4xyatay montaj yapılacaksa

Çatıya Betonla

Tüm ürünler yapacağnız uygulamaya göre delikleri açılmış montaj hazır üretilmektedir. Kesme ölçülendirme ve tadilat gerektirmeden sahada montaj edebilirsiniz.

Hangi açıyla, hangi yükseklikte ve hangi panellerde kullanılacağı özellikler kısmında ayrıntısıyla verilmiştir.

Atakale güneş enerjisi panellerinin kurulumu için galvaniz çelikten güneş enerjisi destek profilleri üretmektedir. Çelik destek profillerimiz soğuk şekillendirilmiş hafif çelik konstrüksiyon profillerden yapılmıştır. Standart destek profillerinin yanında ayrıca müşteri isteklerine göre özel üretim yapabilmekteyiz. İhtiyaçlarınıza yönelik hazır bir tasarımınız varsa lütfen paylaşmaktan çekinmeyin. Yüksek kalite standartları ve en uygun fiyatlarla hizmet veriyoruz. Roll form makinalarımız, PVC pencere ve kapılar için destek profilleri, güneş paneli destek profilleri, U Profil, C Profil ve ayrıca prefabrik yapı profilleri yapabilmektedir. Ayrıca alçı levha (alçıpan) profilleri de üretmekteyiz.

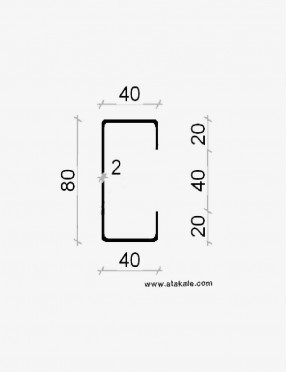

Başka bir avantajımız, farklı çatı senaryoları için farklı destek çözüm seçeneklerimiz var. C ve U şekilli profillerin kombinasyonu farklı yapılar için kullanılabilir. Ayrıca güneş enerjisi paneli destek bağlantılarında U profil ve Z şekilli çelik profiller kullanılabilir.

Bunun yanında roll form makine parkurumuzda farklı şekil ve formlar üretmekteyiz. Profil formlarımızdan bazıları C, U, CEE, ZEE, SIGMA ve SIGMA + ‘dır. Fabrika ortamında her zaman tüm üretim aşamaları tam otomatik roll-form teknolojisi ile yapılır. Bu nedenle üretimimizde ISO ve EN standartlarını takip ediyoruz.Profillerimizde tüm 90 ° köşelerde iç yarıçap minimum 3 mm’dir. Tüm ölçülerimiz TS EN 1993-1-3 standartlarına uygundur.Diğer yandan müşteri isteklerine bağlı olarak farklı çelik hammadde kaliteleri ile imalat yapılabilmektedir; S390GD + Z / S350GD + Z / DX51D + Z / S235 JR / S355 JR.

Kalıp ve aparatlarımızın tasarımı ve üretimi kendi teknik ekibimiz tarafından yapılmaktadır. Taleplerinize uygun özel kesitli ürünlerde delme, bükme, ezme, sıvama, uç boşaltma vb. işlemler ile yarı mamül ve mamül üretimi yapılabilmektedir.

Galvanizli C profil saç kullanımın avantajları

C profil, taban ( D ) yükseklikleri 100 mm ile 400 mm arasında kullanılacak projeye göre değişiklik gösteren, maksimum 4mm kalınlıkta ve maksimum 18 metre boya kadar üretimi gerçekleştirilen galvanizli veya siyah saçdan üretilen profildir.

Projelerde tercih edilen yüksek kaliteli çelikleri kullanarak haddeli şekillendirme ile üretilmiştir. Tercihen boyutsal kesinliğin ve yüksek kaliteli çeliklerin gerektiği inşaat, taşımacılık ve imalat sektörlerinde kullanılır.

Standart çelik derecesi S235J2C+N’dir, diğer çelik dereceleri özel talep doğrultusunda temin edilebilir.

Tüm profiller üretim sırasında otomatik olarak markalama ve pozlama yapılır , böylece şantiyede montaj hızı ve kolaylığı artırılır.

Tüm montaj ve servis delikleri, profilin 3 boyutunda da Autocad çizimlerine göre hazırlanır.

Yüksek hassasiyetli, bilgisayar kontrollü ve tam otomatik hatlarda standartlarına uygun üretim yapılır.

C profil, ağır yüke maruz kalan güneş enerji santrallerinde kolon kiriş ve aşık olarak kullanılır; daha hafif, güneş paneli kurulumlarında ise birincil taşıyıcı kolon, kiriş ve yük taşıyan duvar görevini üstlenirler. C profil GES santral tasarım ve yapımı için çok büyük avantajlar sağlar.

C profil ile daha hızlı, güvenli ve daha ekonomiktir

C profil, her projenin kendi özelliklerine göre değişken kesitlerde üretilir, böylelikle hem hafif hem de yüksek performanslı çözümler sağlanır.

C profil, kendi ağırlığına oranla çok yüksek taşıma kapasitesine sahiptir, bu sayede sıcak hadde kesitlere oranla 50%’ye varan maliyet avantajı yaratırlar.

C profil her projenin tanımlanmış özel ihtiyaçlarına göre farklı mekanik ve korozyon performanslı galvanizli ve sıcak çelik hammaddeden üretilir.

C Profil Yüksek mukavemet ve Yüksek korozyon dayanımına sahiptir.

C Profil Yüksek hassasiyet ile santralin tüm açı ve yerleşim planları CAD CAM yazılımlarıyla kolayca yapılmasını sağlar

C profil Hammadde çeşitliliği yüksektir. Üretimi kolay ve yaygındır