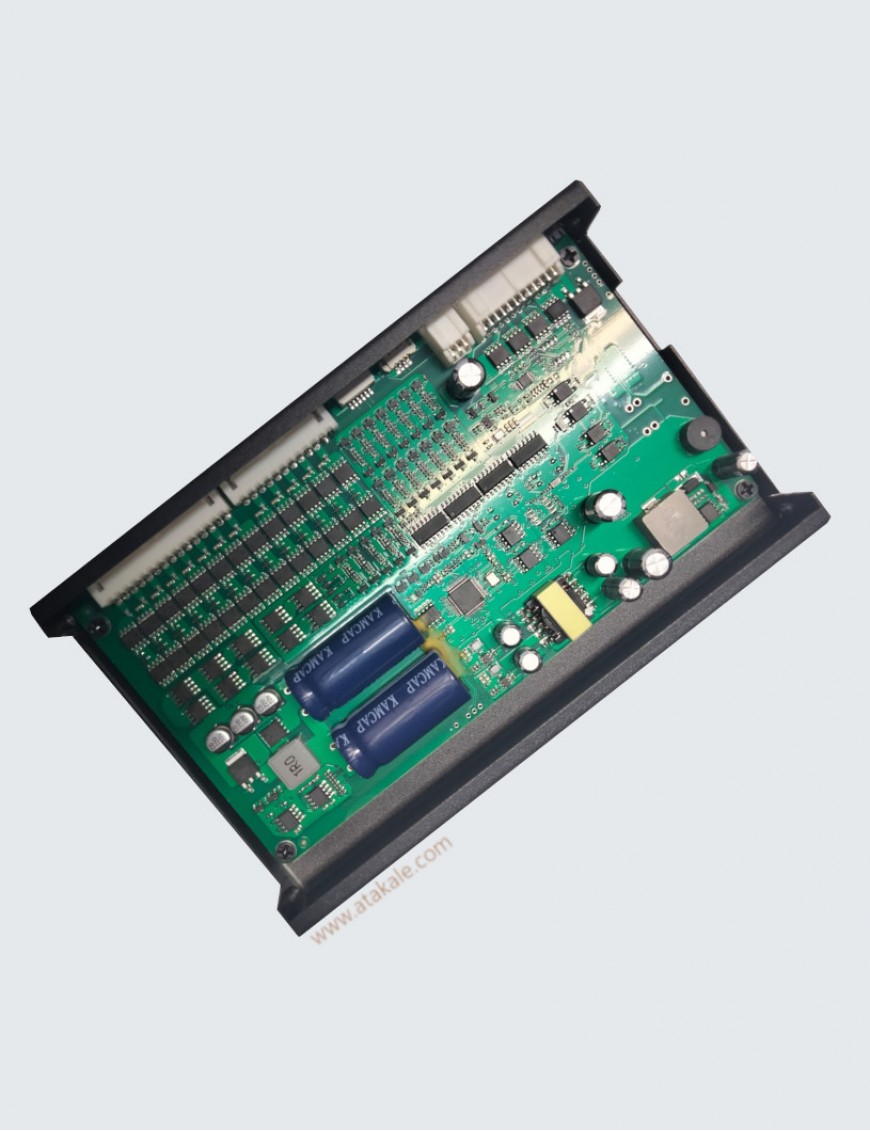

AKTİF - Chengdu Jikong Technology Co., LTD'den dengeleyici.

Chengdu Jikong teknoloji a.ş., LTD. Firmamızın satışını yaptığı donanım ürünleri ve aksesuarlarına kalite garantisi vermektedir. Garanti süresi yukarıda gösterildiği gibidir. Garanti süresi boyunca şirket, ürün arızası ve doğrulama bildirimini aldıktan sonra tüm ürün setini onarmayı veya değiştirmeyi seçme hakkına sahip olacaktır. Yedek ürünlerin tamamı yeni veya yeniye yakın olabilir.

1. Chengdu jikong teknoloji a.ş., ltd. Ürünlerin tamamen test edildiğini garanti eder.

2. Chengdu jikong Technology co., LTD, ürünlerin ürünün onarım sürecinde kesintisiz olarak kullanılabilir. Ancak firma, arızalı ürünlerin makul sürede onarılmasını sağlayacaktır.

3. Garanti süresi, ürünün teslim edildiği tarihten veya chengdu jikong Technology co., LTD. tarafından kurulum tarihinden itibaren başlar. Şirketin ürünleri, kullanıcının programı veya gecikmesi nedeniyle sevkıyat tarihinden itibaren 30 gün içinde kurulmazsa, ürettiğimiz Lityum pil BMS'nin tamamı, 3 yıl kalite garantisini garanti ederiz; hasar, insanın hatalı kullanımından kaynaklanıyorsa, biz gerçekleştireceğiz. Ürünlerin ücretli onarım garanti süresi, onarımı takip eden 31. günden itibaren hesaplanacaktır. Sevkiyat tarihi.

4. Chengdu jikong teknoloji a.ş., ltd. aşağıdaki nedenlerden kaynaklanan herhangi bir ürün arızası veya hasarı için ücretsiz garanti vermez: (a) uygunsuz kullanım veya uygunsuz bakımdan;(b) chengdu jikong Technology co., LTD. tarafından sağlanmayan yazılım, aksesuar, bileşen veya diğer öğelerden;(c) yetkisiz sökme, değiştirme ve yanlış kullanma;(d) ürünün teknik özelliklerinde belirtilen kapsamı aşan kullanım;(e) uygunsuz taşıma, taşıma ve depolama;(f) kitlesel olmayan diğer nedenlerden kaynaklanan arıza veya hasar (örn. deprem) savaş, trafik kazası vb.) Yasaların izin verdiği ölçüde, yukarıdaki garanti tek açık garantidir ve yazılı veya sözlü başka hiçbir garanti yoktur.

Lityum pil akıllı BMS, büyük kapasiteli seri lityum pil paketleri için özel olarak tasarlanmış bir yönetim sistemidir. Gerilim toplama, büyük akımın aktif dengelenmesi, aşırı şarj, aşırı akım, aşırı sıcaklık koruması, Coulombmetre, Bluetooth iletişimi, GPS uzaktan kumandası ve benzeri işlevlere sahiptir. Lityum demir fosfat, lityum üçlü ve diğer pil türleri için uygundur.

BMS, Aktif Dengeleme için Tescilli teknolojimize güvenmektedir. Yüksek akım aktif dengeleme teknolojimiz maksimum pil tutarlılığı sağlayabilir, pil ömrünü uzatabilir, Pilin yaşlanmasını geciktirebilir. BMS, Android V.7 ve üzerini ve IOS işletim sistemlerini destekleyen yardımcı bir mobil APP'ye sahiptir. APP, pilin çalışma durumunu kontrol etmek ve BMS'nin çalışma parametrelerini değiştirmek, şarjı, boşaltma anahtarlarını vb. kontrol etmek için cep telefonunuzdaki Bluetooth aracılığıyla BMS'ye bağlanabilir. BMS, küçük gezi arabaları, yürüyüşçüler, paylaşılan arabalar, yüksek güç depolama, baz istasyonu yedek gücü, güneş enerjisi istasyonları ve diğer ürünlerin pil paketinde yaygın olarak kullanılabilen, küçük boyutlu, kullanımı basit ve işlevlerle doludur. .

Bu, her şeyin Akü Terminalleri / DC Barasında (Paralel Akü Grupları için) doğru Gerilimleri okuması, göndermesi/alması için önemlidir.

Bir SCC veya İnvertör/Şarj Cihazı vb. @ 25,6/51,2'de şarj olurken Pillerin NE GÖRDÜĞÜNDEN emin olmanız gerekir. Aksi takdirde, diferansiyel bir Uyuşmazlığa neden olur ve SCC'de veya DC Barasındaki herhangi bir Şarj Cihazında (*2) bir hata (*1) oluşturur.

BMS, Pil ve Hücre Gerilim Durumlarını ölçen EN Hassas cihazdır. Bu, Tek Pil veya Pil Grubu için geçerlidir.

Tüm SCC'lerin veya Şarj Cihazlarının içinde bir Telafi/Düzeltme ayarı yoktur. Bu nedenle, bu farkı telafi etmek için "Matematik" yapmanız gerekir. Bu nedenle, bu tür olayları önlemek için SCC, Şarj Cihazı ve Akü Terminalleri/Veriyolunda Gerilim Ölçümleri "almalı" ve ardından istediğiniz Şarj Profilinize uyacak ayarlamalar yapmalısınız.

En az 2 Ondalık Basamak voltaj göstergesine sahip bir Dijital Multimetre / Dijital Volt/Ohm Metrenin bunu yapması En Yüksek Derecede Tavsiye Edilir. Tek Haneli bir cihaz herhangi bir şey için ÇOK DOĞRUDUR

Lityum Tabanlı Pil veya hücre.

(*1) Bu, Aşırı/Düşük voltaj okumasının bir hatayı tetiklemesiyle sonuçlanabilir. Bunun altında veya üstünde ise, bir Pil içindeki bir veya daha fazla hücrenin hücrelerin Çalışma Gerilimi Aralığını (3.000-3.400) çalıştırıp yenebileceği ve bir BMS Arızasını tetikleyebileceği "Koşucu Hücre" durumunu da yaratabilir. Bu, yeni/yeni ürünlerde Çok Yaygındır

Gerilim açısından Düzeltilmemiş ve Dengelenmemiş kurulumlar.

(*2) TÜM DC Hatlarının kablo uzunluğu boyunca bir miktar kayıp yaşayacağını unutmayın. Bunlar toplu olarak her terminali, pabucu, cıvatayı, anahtarı ve hatta sigortaları ve kesicileri içerir. Her bir "öğe" büyük olmasa da (bir Arıza olmadığı sürece), kolektif olarak oldukça hızlı bir şekilde toplanabilirler. Bu, Lityum Tabanlı teknolojinin kullanılmasıyla ilgili bir "doğruluk" gereksinimi sorunudur.

Üretilen tüm Lityum pil BMS'lerimiz, 3 yıl kalite garantisi veriyoruz, hasar insan tarafından yanlış işlemden kaynaklanırsa, ücret karşılığında onarım yapacağız

1. BMS profesyonel bir aksesuardır.Birçok çalıştırma hatası ürünün hasar görmesine neden olur, bu nedenle lütfen uyumluluk işlemi için talimat kılavuzunu veya kablolama video eğitimini izleyin.

2. BMS'nin B- ve P- kablolarını ters bağlamayanız, kablolamayı karıştırmayınız

3.Li-ion, LiFePO4 ve LTO BMS evrensel değildir ve farklı BMS kullanılması grekir, karışık kullanamazsınız

4.BMS yalnızca aynı dizilere sahip pil takımlarında kullanılabilir.

5. Aşırı akım durumu için BMS'yi kullanmak ve BMS'yi makul olmayan bir şekilde yapılandırmak kesinlikle yasaktır.BMS'yi nasıl doğru seçeceğinizi bilmiyorsanız lütfen müşteri hizmetlerine danışın.

6. Standart BMS'nin seri veya paralel olarak kullanılması yasaktır.Paralel veya seri bağlantı kullanılması gerekiyorsa detaylar için müşteri hizmetlerine danışınız.

7. Kullanım sırasında BMS'nin izinsiz sökülmesi yasaktır.BMS, özel olarak söküldükten sonra garanti politikasından yararlanmaz.

8. BMS'mizin su geçirmez işlevi vardır.Bu pimler metal olduğundan, oksidasyon hasarını önlemek için suya batırılmaması gerekir

9. Lityum pil paketinin özel lityum pil ile donatılması gerekir şarj cihazı, diğer şarj cihazları karıştırılamaz, voltaj dengesizliği vb. önlemek için MOS tüpünün bozulmasına neden olur.

10.Smart BMS'nin özel parametrelerini değiştirmeden revize etmek kesinlikle yasaktır. izin.Değiştirmeniz gerekiyorsa lütfen müşteri hizmetlerine başvurun.Yetkisiz parametre değişikliği nedeniyle BMS'nin hasar görmesi veya kilitlenmesi durumunda satış sonrası servis sağlanamaz.

11. DALY BMS'nin kullanım senaryoları şunları içerir: Elektrikli iki tekerlekli bisiklet, forkliftler, turistik araçlar, E-üç tekerlekli bisikletler, düşük hızlı Dört tekerlekli, RV enerji depolama, fotovoltaik enerji depolama, ev ve dış mekan enerji depolama vb. BMS'nin özel koşullarda veya amaçlarla kullanılmasının yanı sıra özelleştirilmiş parametreler veya fonksiyonlar, lütfen önceden müşteri hizmetlerine danışın.

1. Koruyucu pano bağlantısı akü kablolarının sırası:

Özel dikkat: Farklı üreticilerin tel kabloları aynı standartta değildir, lütfen he-uyumlu kablolar kullandığınızdan emin olun; farklı üreticilerin B ve P çizgilerinin renkleri farklıdır, lütfen B ve P işaretlerine dikkat edin.

1. Unutma!!! Örnekleme tel kablosunu kaynak yaparken, kabloyu BMS'ye sokmayın.

2. Kablo, toplam negatif elektrot B'yi ince siyah çizgiden bağlar. İkinci kablo (kırmızı kablo), ilk pil dizisinin pozitif kutbuna bağlanır. Her pil dizisinin pozitif elektrotunu, toplam pozitif B+'nın son kablosuna kadar sırayla bağlayın.

JK 500A Balancer BMS

Çift taraflı aktif balans teknolojisi

Aktif Balans ve Kablosuz yönetim

Tamamen boş akü, yönetim yazılımı

Fonksiyon güvenlik kontrol,4 katman

ISO 26262 standartlarında koruma

IOS, Android uygulama ve yönetim

Kapasite Yönetimi UART,RS485,CAN

Lithium ternary , lithium iron phosphate

BMS Voltaj Aralığı

BMS Akım Kapasite Aralığı

Hücre Sayısı Aralığı

Gümrük tarife GTIP :8536300000

Profesyonel Proje Ürün Gurubudur. Ürün sipariş edildiğinde sizin için 7 gün içinde üreticiden /ithalatçıdan tedarik edilerek özel sipariş olarak gönderilecektir. Aceleniz var ise lütfen iletişme geçerek stok öğrendikten sonra satın alınız. Son Kullanıcı Tüketici Elektronik Ürünü Değildir. Satın Alma Şartları , değişim , iade ve garanti şartları tüketici korunma haklarınını içermez. Ticaret Kanunu hükümleri geçerlidir. Sadece bayi ve tüccarlara satış yapılmaktadır. Satın alan kişi bu ürünü kullanmaya yeterli bilgisi ve eğitimi yok ise almamasını tavsiye ediyor.

HS Code : 8507909000

Chengdu Jikong Technology Co. Dünyanın en büyük BMS/Batarya Yönetim Sistemi üreticisidir. Ürünlerinin tamamında araştırma ve geliştirilmeye odaklanan bir çin firmasıdır. "Lityum pil aktif dengeleme teknolojisinin lideri" olarak Chengdu Jikong teknolojisi, dünyanın önde gelen akü yönetim sisteminin dört temel teknolojisinde uzmanlaştı: aktif dengeleme, kablosuz iletim, işlevsel güvenlik ve kapasite yönetimi. "Ürünlerin mükemmelliğini takip etmek, çevre koruma amacına yardımcı olmak ve güzel bir dünya için uzay teknolojisi, elektrikli araç endüstrisinde yeni bir sayfa yazdı ve çevre korumaya katkıda bulundu. !

JK BMS, farklı uygulamalar için Bluetooth/RS485/Wifi/RS232/TTL232/CANBUS'u destekleyen yüksek kaliteli BMS/Dengeleyici/Monitörler serisi tasarlamak için profesyonel Hücre BMS/Hücre Dengeleyici/Akü monitörleri konusunda uzamn ekibe sahiptir. Özel ürünlerle ilgili ve projelerinizle ilgili mühendis ekibimizle irtibata geçebirlisniz.

JK BMS, elektronik/pil BMS alanında 10 yıldan fazla deneyime sahip, li-ion, lifepo4, NMC, Ni için en yenilikçi ve yüksek kaliteli aktif pil dengeleyici ve aktif dengeleyici BMS'yi tasarlama ve üretme gücüne sahip profesyonel bir BMS dir. -MH,Ni-Cd, Kurşun asit aküler, kırmızı akışlı aküler, VRLA ve AGM aküler, vb.. JK dengeleyici ve BMS, israf edilmeyen ancak akü içinde yeniden dağıtılan aktif dengeleme teknolojisini kullanır. Pasif dengeleme gibi atık ısı olmadığından bunun için soğutmaya da gerek kalmıyor. Karşılaştırılabilir performansla daha az alan gerekir. Optimum dengeli akü, kullanım ömrünü önemli ölçüde artırır.

Büyük kapasiteli seri lityum pil paketleri için tasarlanan lityum batarya hücresi akıllı BMS, voltaj toplama, aktif büyük akım dengeleme, aşırı şarj, aşırı akım, aşırı sıcaklık koruması, Coulombmetre, Bluetooth bağlantısı, GPS uzaktan kumandası dahil olmak üzere bir çok özellik sağlayan bir yönetim sistemidir.BMS lerinde Aktif Dengeleyici , yüksek akım aktif dengeleme teknolojisi, maksimum pil tutarlılığı, daha uzun pil ömrü ve gecikmiş pil yaşlanması dahil olmak üzere bir dizi avantaj sunar.

JK Marka BMS lerde hem lityum demir fosfat, hemde lityum ion hücrelerle aynı BMS kullanılabilir.

Ana Özellikler

JK-B2A25S-RP aktif dengeleme yönetim sistemi (BMS), büyük kapasiteli (yüksek akım ve seri halinde birçok hücre) lityum pil paketleri için tasarlanmıştır. Üçlü lityum, lityum Titanat (LTO) vb. gibi diğer hücre türleriyle çalışacak şekilde yapılandırılabilir.

Sistem seri bağlı 3 ila 25 hücreyi destekler. JK-B2A25S-RP standart BMS işlevlerini yerine getirir; yani aşağıdakilere karşı koruma sağlar: aşırı/düşük hücre sıcaklığı, aşırı şarj veya deşarj akımları,

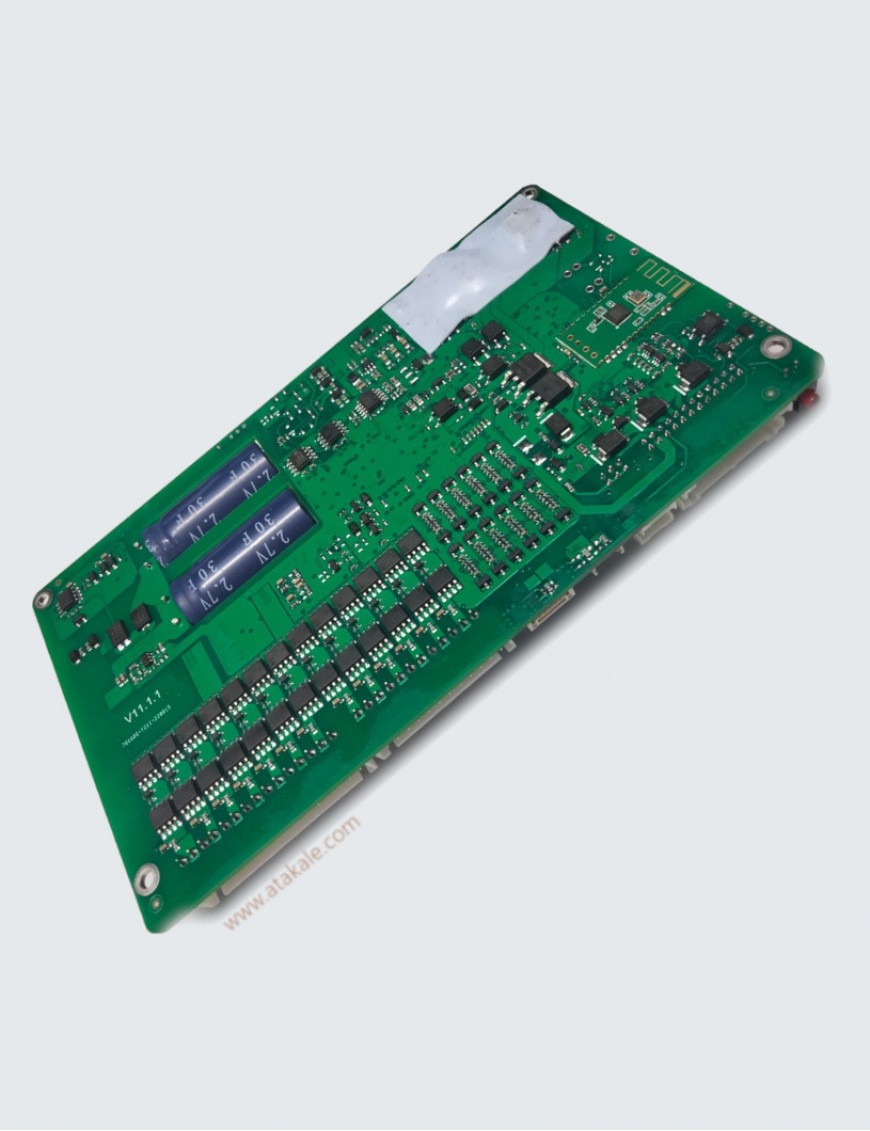

aşırı/düşük hücre voltajları JK-B2A25S-RP ayrıca aktif bir hücre dengeleme işlevi de gerçekleştirir. Aktif dengeleme, enerjiyi en yüksek yüklü hücreden (en yüksek gerilime sahip hücre) alır ve bunu bir süper kapasitör aracılığıyla en düşük gerilime sahip hücreye aktarır.

Aktif olunduğunda süreçte herhangi bir enerji kaybı yaşanmaz (pasif dengelemede dengeyi sağlamak için dirençler kullanılır ancak bu çok fazla enerji kaybına neden olur). Dengeleme, BMS'ye bağlı olduğu ve güç sağladığı sürece gerçekleşir. Dengeleme, bitişik hücrelerin aşırı veya düşük şarjlı olabileceği durumları önler (örn. 3V ve 3,6V iso'nun her ikisi de 3,3V'dir) Dengeleme (işlevi gerçekleştirmek için yeterli süre geçtikten sonra) hücreyi korur. Hücrelerin birbirinden 5mV ila 10mV (ayarlanabilir) arasındaki voltaj farkı aralığında dengeleme sağlanır. Dengeleme, akünün hcrelerinde kullanılabilir kapasitesini ve genel ömrünü artırır. Daha küçük kapasiteli BMS ünitelerinin aksine JK-B2A25S-RP, bir arıza durumu oluştuğunda akünün bağlantısını kesmek için dahili yarı iletken anahtarlama elemanları içermez.

Bağlantının kesilmesi, harici olarak monte edilen yüksek akım solenoidleri (röleler) aracılığıyla gerçekleştirilir. İhtiyaca bağlı olarak bu solenoidlerden en fazla 3 tanesine ihtiyaç duyulabilir (ön şarj, aşırı şarj, aşırı deşarj). Solenoidler BMS ile birlikte verilmemektedir ve bunların dışarıdan temin edilmesi gerekmektedir.

JK-B2A25S-RP, parametreleri ayarlamanıza ve hücrelerin durumunu izlemenize olanak tanıyan yerleşik Bluetooth desteğine sahiptir. Eşleşen bir Android/Apple Uygulamasının yüklenmesi gerekiyor

Teknik Özellikler Desteklenen maksimum hücre sayısı: 25 hücre

Desteklenen minimum hücre sayısı: Bağlı hücreler (12V) tarafından çalıştırılıyorsa yaklaşık 4

Maksimum Anahtarlama Akımı: Bu solenoidin bir fonksiyonudur. Tipik olarak 500A (1000A tepe noktası)

Dengeleme Akımı: 2A

Hücre teknolojileri: LFP, NMC, LTO vb. CAN Desteği: CAN 2.0A. Durum mesajlarını 250kbps hızında iletin

Bluetooth Desteği: Evet | JIKONG BMS Uygulaması *Tüm ürün özellikleri ve ürün görselleri önceden haber verilmeksizin değiştirilebilir.

Can Otobüs İşletmeciliği

JK-B2A25S-RP, yerleşik bir STM32F103 sınıfı mikro denetleyiciye sahiptir. 250kbps'de CAN2.0A standardına göre CAN veri yolu iletişimlerini destekler. BMS yalnızca durum bilgisini iletir (hiçbir mesajı almaz veya yanıt vermez). Mesaj döngüleri ve kimlikleri aşağıdaki gibidir:

Paketleme Bilgileri

JK-B2A25S-RP | Hücrelere bağlanmak için kablolar (hücre tarafında açık uçlu) Sıcaklık sensörlü kablo (3) | Solenoidlere, akım sensörüne, CAN'a vs. bağlanmak için kablo (uzak uçta açık uçlu) | Akım sensörü şönt direnci

JK-B2A25S-RP pil yönetim sistemi (BMS), büyük kapasiteli (yüksek akım ve seri halinde birçok hücre) lityum pil paketleri için tasarlanmıştır.

Üçlü lityum, lityum Titanat (LTO) vb. gibi diğer pil türleriyle çalışacak şekilde yapılandırılabilir.

Sistem seri bağlı 3 ila 25 hücreyi destekler.

JK-B2A25S-RP standart BMS işlevlerini yerine getirir, yani aşağıdakilere karşı koruma sağlar:

a) aşırı/düşük hücre sıcaklığı,

b) aşırı şarj veya deşarj akımları

c) aşırı/düşük hücre voltajları

JK-B2A25S-RP ayrıca aktif hücre dengeleme işlevini de yerine getirir.

Aktif dengeleme, enerjiyi en yüksek yüklü hücreden (en yüksek gerilime sahip hücre) alır ve bunu bir süper kapasitör aracılığıyla en düşük gerilime sahip hücreye aktarır.

Aktif olunduğunda süreçte herhangi bir enerji kaybı yaşanmaz (pasif dengelemede dengeyi sağlamak için dirençler kullanılır ancak bu çok fazla enerji kaybına neden olur).

Dengeleme, BMS hücrelere bağlı olduğu ve hücreler tarafından çalıştırıldığı sürece gerçekleşir.